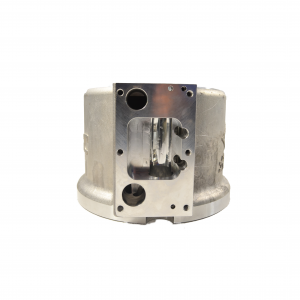

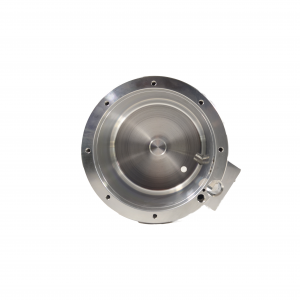

Aluminum alloy gravity casting OEM for automotives

Product description

The casting manufacturing process is commonly used in several fields such as engineering, agriculture, automotive, road, and construction. Metal casting has wide suitability. According to different needs, the wall thickness for casting walls can vary from 0.3-1000 mm, the weight varies from grams to more than 300 tonnes, and the length ranges from millimetres to ten meters. Additionally, metal casting has a relatively low cost compared to other materials because of its flexible production methods, reusable character, and low power consumption.

Tianhe Casting is an aluminum alloy manufacturer. We take OEM orders from customers with their own drawings or ideas. We are also able to provide 3D scanning for the parts customer are expecting to duplicate. We are able to produces aluminium parts of different dimensions, weighing from 50g to 100kg. We have the ability and experience to develop collaboratively with customers and have design and development software such as PRO/E, UG, AutoCAD, and Any Casting. In 2020, our annual production output reached more than 7000 tones.

In order to prove our product quality in casting, we have implemented 3 automatic casting lines and 3 automatic dosing furnaces. The new equipment has not only helped us control the accurate amount of molten metal into the casting machine but also reduced the potential work hazard for employees.

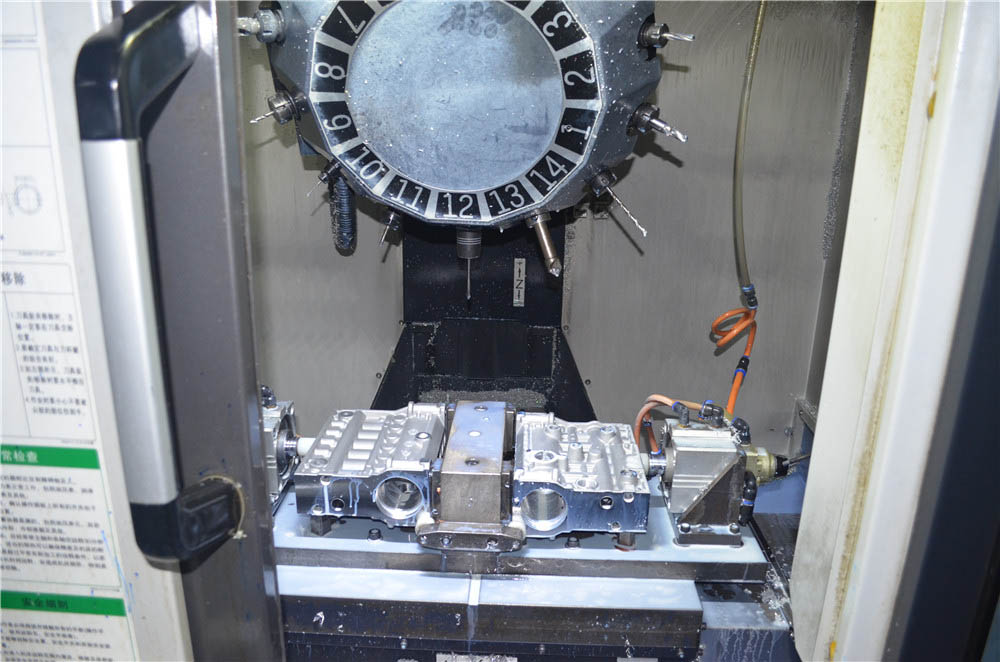

We are also able to manufacture Aluminum profiles. The main equipment in our CNC factory includes more than 100 CNC machines from Brothers and Doosan, 3 horizontal CNC machines, 6 CNC Tapping centres, 19 CNC Milling machines, 23 CNC horizontal lathing machines, a centreless Grinding Machine, and an Industrial washer.

In February 2008, we successfully passed the ISO/TS 16949:2002 quality system certification. In 2016, we have acquired the IATF 16949: 2016 certification, adding extra quality assurance to our products.

Please note: The products we are displaying are strictly for demonstrating manufacturing capacity. All the designs belong to our customers that we cannot sell the products to others.

FAQ

- 1.How large is your company? What is the annual output value?

Our total revenue in 2020 was ¥270 million CNY ($45 million USD).

2.How long is the normal use of your mold?

A metal mould would normally last 100,000 makes.

3.What certifications has your company passed?

We have IATF 16949:2016, ISO14001:2005 and ISO45001:2018.

4.What patents and intellectual property rights does your product have?

We have more than 40 patents in casting and machining field, including 4 inventional patents.

5.How long does it take for your company's mould development?

Our mould development often takes 30-45 days.

OEM order process

1. Customer Provide Drawings

2. Engineers provide quote for customer

3. Quote accepted by customer

4. Sample mold making

5.Send the first samples and mould for customer inspection

6. Casting

7. CNC Machining

8. Quality control

9. Surface treatment