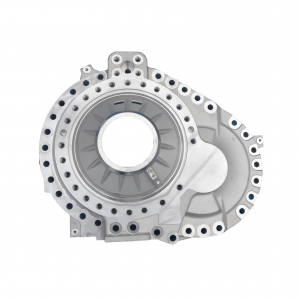

Customised gravity Iron casting for automotives

Product description

The casting manufacturing process is commonly used in several fields such as engineering, agriculture, automotive, road and construction. Casting is a process of melting metal into permeant or one-off mould to create a product with anticipated dimensions and shape.

Tianhe Casting is an iron and aluminium alloy casting manufacturer. We take OEM orders from customers with their own drawings or ideas. We are also able to provide 3D scanning for the parts customer are expecting to duplicate. We are able to produce metal parts of different dimensions, weighing from 50g to 100kg. We have the capacity of producing highly complex parts with different dimensions and geometries. We have experience of developing collaboratively with customers and has designing and developing software such as PRO/E, UG, AutoCAD, and AnyCasting.

In 2020, our annual production output reached more than 7000 tonnes. We are committed to technology improvement and quality systems. In February 2008, we successfully passed the ISO/TS 16949:2002 quality system certification. In 2016, we have acquired the IATF 16949: 2016 certification, adding extra quality assurance to our products.

Please note: The products we are displaying are strictly for demonstrating manufacturing capacity. All the designs belong to our customers that we cannot sell the products to others.

Why do our customers work with us?

1.Aluminium alloy casting service

2.Iron casting service

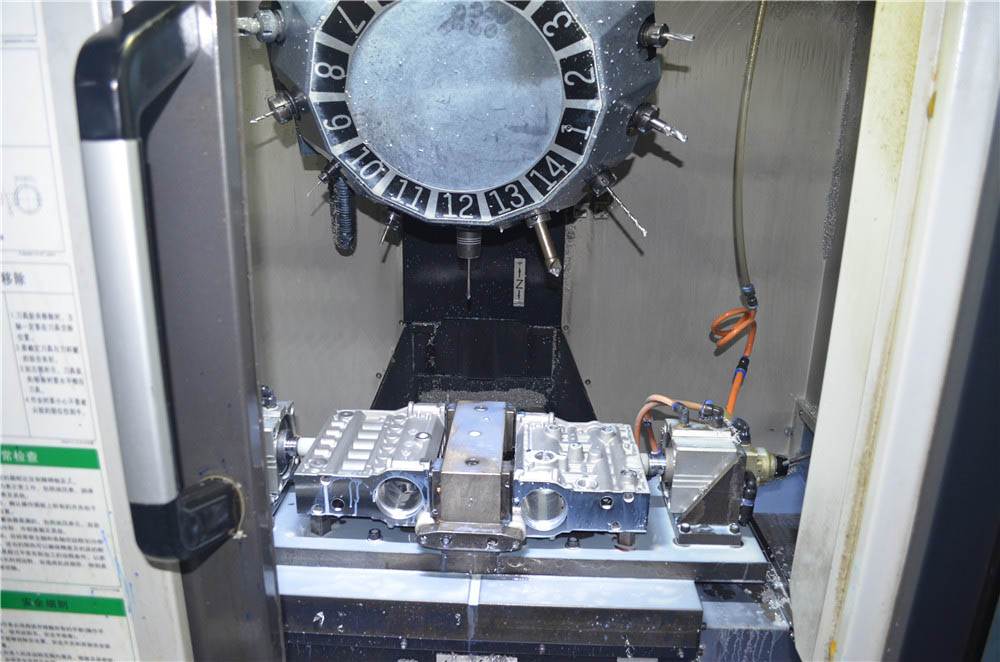

3.CNC machining

4.Customisation from 2D or 3D drawings

5.Engineers with more than 20 years of experience in casting

6.Competitive pricing

7.Tailored tooling design service

8.On-time delivery even during covid-19 pandemic

FAQ

1.Can your products carry a guest's LOGO?

Yes, we can do logo customization for MOQ of 100 pcs.

2.Can your company distinguish the products your company produces?

Yes, we have our unique supplier code on our product so that the customers can distinguish our product from other suppliers.

3.How are your products made up? What are the specific materials?

We are specializing in gravity casting, low-pressure casting and precision CNC Machining. We are able to undertake a wide variety of metal materials such as brass, bronze, stainless steel, aluminium alloy and iron etc.

4.How long does it take for your company's mould development?

Our mould development often takes 30-45 days.

5.Does your company charge mould fees? Can it be returned? How do we return it?

Yes, we do charge metal mould fees but it is a one-off fee. It is a non-refundable fee.

OEM order process

1. Customer Provide Drawings

2. Engineers provide quote for customer

3. Quote accepted by customer

4. Sample mold making

5.Send the first samples and mould for customer inspection

6. Casting

7. CNC Machining

8. Quality control

9. Surface treatment