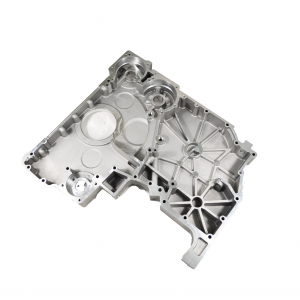

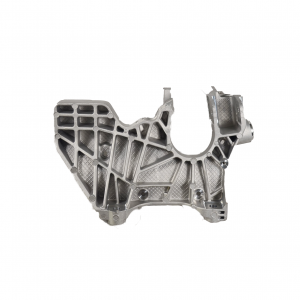

low pressure aluminum alloy casting parts for engine housing cover

Product description

Aluminum alloy has a wide range of advantages thanks to its lightweight and versatile characteristics. Aluminum alloy product has a controlled surface finish, dimensional accuracy, and complex geometries. What’s more, aluminium alloy can withstand higher temperatures compared to other metals, enabling greater and more stable performance in the automotive field and even the aerospace field.

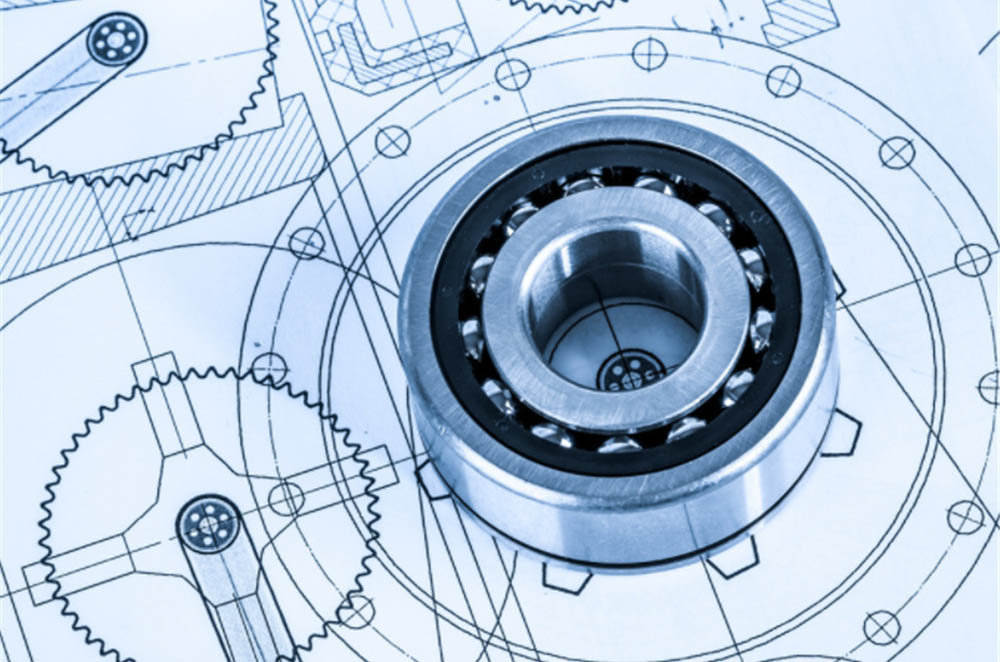

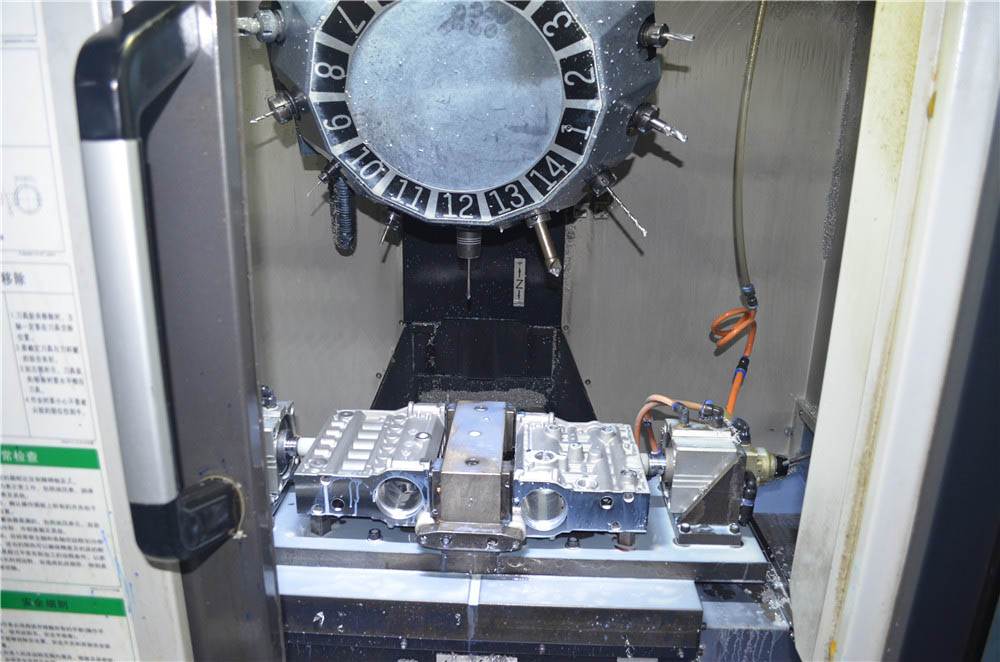

We take OEM orders from customers with their own drawings or ideas. We produce metal parts of different dimensions, weighing from 50g to 100kg. We are able to reach an RA of 0.2 and the highest tolerance is +-0.005 mm. The software we are using includes PRO/E, UG, AutoCAD, and AnyCasting. Our normal delivery time is within 45-60 days depending on the complexity of the product. In 2020, our annual production output reached more than 7000 tonnes, 80% in aluminium alloy.

In February 2008, we successfully passed the ISO/TS 16949:2002 quality system certification. In 2016, we have acquired the IATF 16949: 2016 certification, adding extra quality assurance to our products. Moreover, in order to prove our product quality in casting, we have implemented 3 automatic casting lines and 3 automatic dosing furnaces. The new equipment has not only helped us control the accurate amount of molten metal into the casting machine but also reduced the potential work hazard for employees.

Please note: The products we are displaying are strictly for demonstrating manufacturing capacity. All the designs belong to our customers that we cannot sell the products to others.

FAQ

1.How are your products made up? What are the specific materials?

We are specializing in gravity casting, low pressure casting, and precision CNC Machining. We are able to undertake a wide variety of metal materials such as brass, bronze, stainless steel, aluminium alloy, and iron, etc.

2.Can your company distinguish the products your company produces?

Yes, we have our unique supplier code on our product so that the customers can distinguish our product from other suppliers.

3.What is your company's production process?

Please visit our OEM page for more information.

4.Are your products traceable? If so, how was it achieved?

We have our unique product code and supplier code on each product. It is traceable throughout the mould process to CNC Machining.

5.What benefits does your company have, and which ones can reflect your company's sense of social responsibility?

We are promising to have at least 25% of disabled people in our company. We are aiming to provide them with the most suitable working environment and help.

OEM order process

1. Customer Provide Drawings

2. Engineers provide quote for customer

3. Quote accepted by customer

4. Sample mold making

5.Send the first samples and mould for customer inspection

6. Casting

7. CNC Machining

8. Quality control

9. Surface treatment