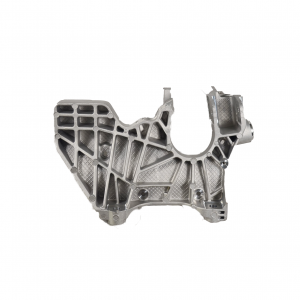

Low Pressure Aluminum Casting for High Precision Parts

Product description

Aluminium casting is a method for producing high tolerance and high-quality parts by pouring molten metal in a precisely designed metal or sand mould. Aluminum alloy often forms a thin layer of aluminum oxide after coming out of a mould. The aluminum oxide layer offers protection against rust and corrosion which made aluminium the perfect material for aerospace, automotive, heatsink, agricultural equipment etc. Moreover, aluminium alloy has a wide range of surface treatments such as clear or coloured anodizing, shot blasting, polishing, electrophoresis coasting, sand coating.

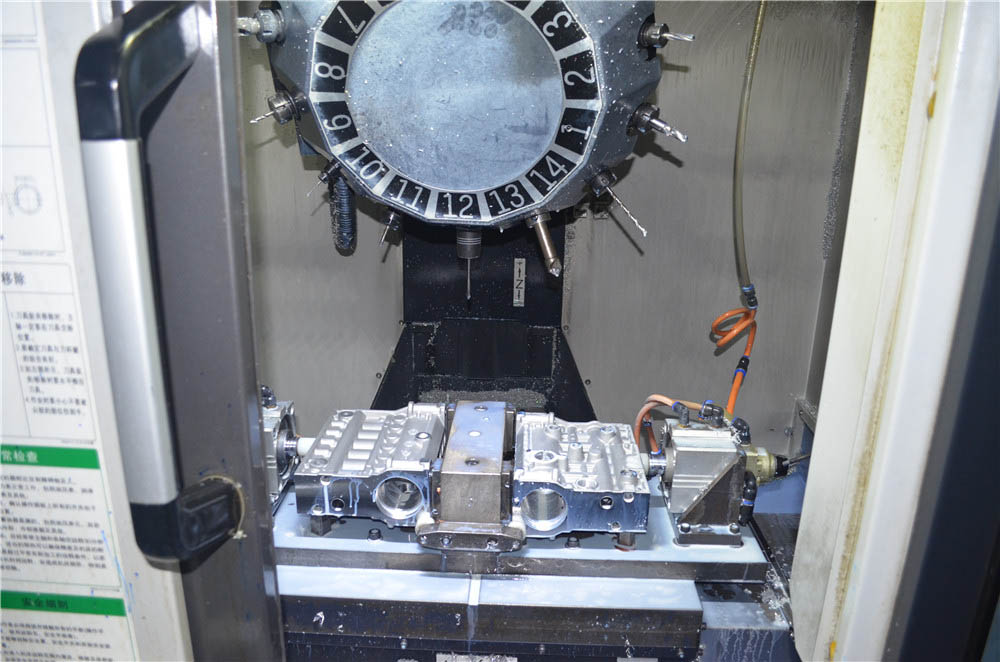

As a die casting and CNC Machining OEM service provider, Tianhe Casting strictly follows the IATF 16949:2016 standards with APQP ( Advanced Product Quality Planning ), Tooling Design, Internal and External quality check, and Part Production Monitoring, etc. Our OEM order process starts with customers providing the drawings of the product they are expecting to make. We will make our initial quote pricing based on the 2D and 3D drawings provided by the customer. Then we will design the mould and make the first batch of samples for the customer's review. We are able to reach an RA of 0.2 and the highest tolerance is +-0.005 mm. The software we are using includes PRO/E, UG, AutoCAD, and AnyCasting. Our normal delivery time is within 45-60 days depending on the complexity of the product. In 2020, our annual production output reached more than 7000 tonnes, 80% in aluminium alloy.

In addition, we have acquired IATF 16949:2016 certificate in 2016 and been using lean manufacturing techniques in our production process to make sure product quality.

Please note: The products we are displaying are strictly for demonstrating manufacturing capacity. All the designs belong to our customers that we cannot sell the products to others.

FAQ

1. How are your products made up? What are the specific materials?

Yes, we can do logo customization for MOQ of 100 pcs.

2. How long is the normal use of your mould?

A metal mould would normally last 100,000 makes.

3. What is your company's production process?

Please visit our OEM page for more information.

4. How large is your company? What is the annual output value?

Our total revenue in 2020 was ¥270 million CNY ($45 million USD).

5. What testing equipment does your company have?

Please visit our Quality control page for more information regarding our test equipment.

OEM order process

1. Customer Provide Drawings

2. Engineers provide quote for customer

3. Quote accepted by customer

4. Sample mold making

5.Send the first samples and mould for customer inspection

6. Casting

7. CNC Machining

8. Quality control

9. Surface treatment