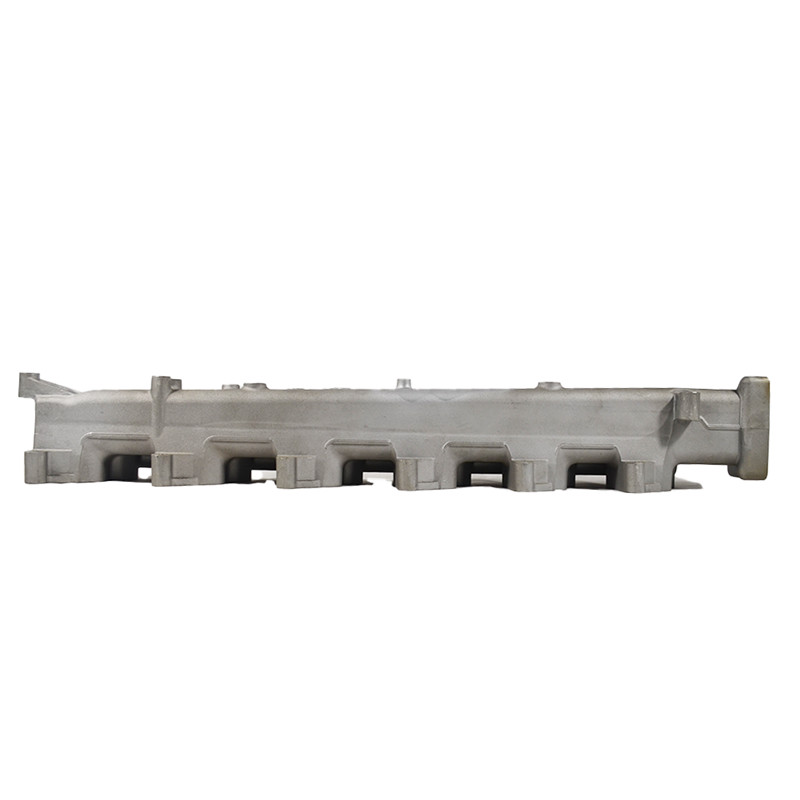

Low-pressure casting pipe aluminium alloy

What is Low Pressure Die Casting (LPDC)?

The common die casting methods include gravity casting and pressure die casting. Gravity die casting is using gravity to fill the mould with molten metal. The gravity casting machine will normally tilt at a certain angle so the molten metal will pour into the mould with the help of gravity. Low pressure die casting is using constantly applied pressure to fill the mould with molten metal.

What are the advantages of low pressure casting?

1.Oxidation and porosity is largely reduced through LPDC process in order to reach a high product consistency and dimension accuracy.

2.Smooth surface finish compared to sand casting.

3.Complex inner structure can be reached by applying a sand core inside the mould.

4.Better mechanical properties.

What are the advantages of working with Tianhe Casting Group?

1. IATF16949:2016, ISO 14001, OHSAS 18001 certified.

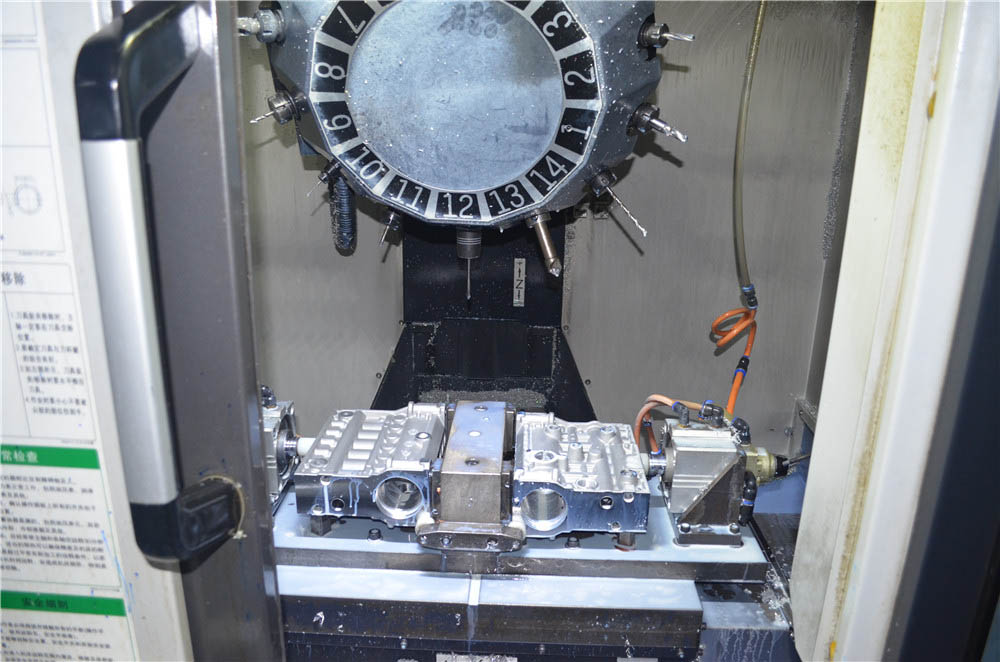

2. We have advanced automation technology and equipment, making sure the products come out in a consistent pace.

3. Product weight range: From 0.05kg to 100kg.

4. Mould life: usually 50,000-10,000 shots.

5. Short lead time: from 30-60 working days.

6. Reliable and experienced supplier for over 20 years.

7. Complete assembly is available. We can assemble, package, label, and also provide all possible related services including but not limited to flexible logistics services

OEM order process

1. Customer Provide Drawings

2. Engineers provide quote for customer

3. Quote accepted by customer

4. Sample mold making

5.Send the first samples and mould for customer inspection

6. Casting

7. CNC Machining

8. Quality control

9. Surface treatment