Low pressure iron casting and cnc machining service

Product description

The casting manufacturing process is commonly used in several fields such as engineering, agriculture, automotive, road, and construction. Metal casting has many advantages such as wide suitability. According to different needs, the wall thickness for casting walls can vary from 0.3-1000 mm, the weight varies from grams to more than 300 tonnes, and the length ranges from millimeters to ten meters.

Tianhe Casting is an iron and aluminium alloy casting manufacturer. We take OEM orders from customers with their own drawings or ideas. We are also able to provide 3D scanning for the parts customer are expecting to duplicate. We are able to produce metal parts of different dimensions, weighing from 50g to 100kg. We are able to reach an RA of 0.2 and the highest tolerance is +-0.005 mm. We have designing and developing softwares such as PRO/E, UG, AutoCAD, and AnyCasting. In 2020, our annual production output reached more than 7000 tonnes.

We are committed to technology improvement and quality systems. While absorbing and digesting advanced technologies from the domestic factory to international companies, we continue to strengthen corporate management and actively implement systematic quality management. In February 2008, we successfully passed the ISO/TS 16949:2002 quality system certification. In 2016, we have acquired the IATF 16949: 2016 certification, adding extra quality assurance to our products.

Please note: The products we are displaying are strictly for demonstrating manufacturing capacity. All the designs belong to our customers that we cannot sell the products to others.

Why do our customers work with us?

1.Aluminium alloy casting service

2.Iron casting service

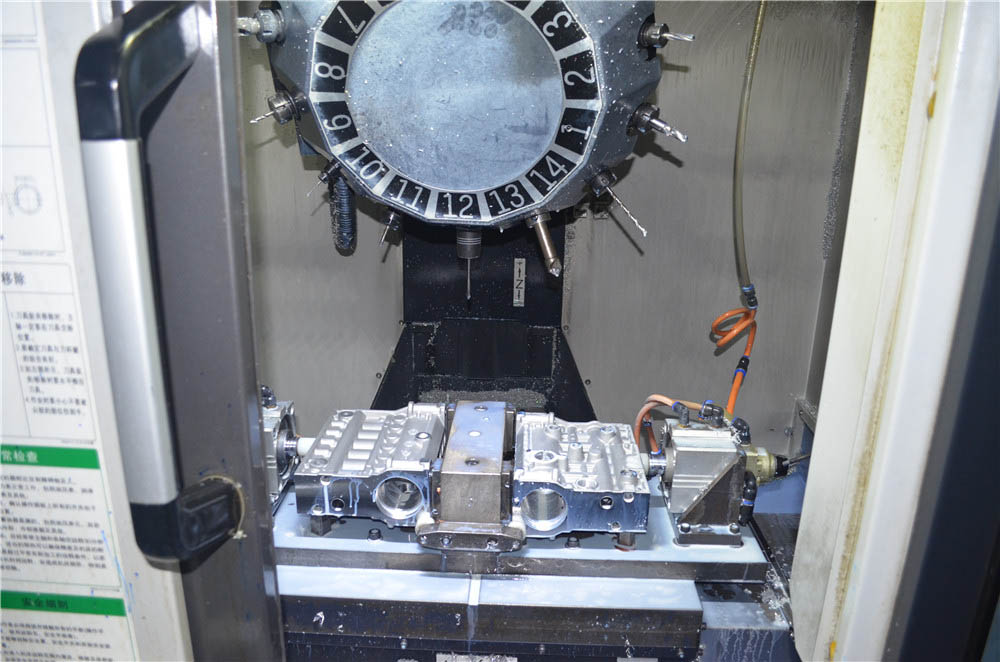

3.CNC machining

4.Customisation from 2D or 3D drawings

5.Engineers with more than 20 years of experience in casting

6.Competitive pricing

7.Tailored tooling design service

8.On-time delivery even during covid-19 pandemic

FAQ

1.What certifications has your company passed?

We have IATF 16949:2016, ISO14001:2005, and ISO45001:2018.

2.What patents and intellectual property rights does your product have?

We have more than 40 patents in the casting and machining field, including 4 inventional patents.

3.Which customers' factory inspections have your company passed?

We have now passed the Global Quality System proposed by Cummins Chongqin Engines Group.

4.How long is the normal use of your mould?

A metal mould would normally last 100,000 makes.

5.What is your company's production process?

Please check our OEM order process.

OEM order process

1. Customer Provide Drawings

2. Engineers provide quote for customer

3. Quote accepted by customer

4. Sample mold making

5.Send the first samples and mould for customer inspection

6. Casting

7. CNC Machining

8. Quality control

9. Surface treatment