As the concern for global warming grows, the whole society is paying more attention to greenhouse gas emissions ( GHG).

According to the Inventory of U.S. Greenhouse Gas Emissions and Sinks 1990-2020, transportation[L1] accounted for more than a quarter of the total GHG emissions in the USA. Cars, trucks, commercial aircraft and railroads are all included in the transportation sector.

Early in 2016, automotive companies have already started the process of weight reduction to cope with the stricter environmental rules and in response to reducing emissions for automotive.

The automotive industry is the main market for aluminium castings, for example, in Japan, 76% of aluminium castings, and 77% of aluminium die-cast parts for automotive castings.

Aluminium castings are mainly used in engine cylinder blocks, cylinder heads, pistons, intake manifolds, rocker arms, engine mounts, air compressor connecting rods, actuator housings, clutch housings, wheels, brake parts, handles and hood housing type parts, etc.

Inevitably, there are defects in aluminium castings, die castings cannot be heat-treated, so the production of aluminium alloy to require higher strength castings are limited.

For this reason, in the casting production process for improvement, the casting forging method and semi-solid forming method will be the future more with the process.

[L1]https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions

Lightweighting cars are good for energy saving and emission reduction, research indicates that a 10% weight reduction of the whole car can reduce fuel consumption by 6% to 8% and save electricity by 6% to 9%.

For every 10% reduction in vehicle weight, emissions can be reduced by 5% to 6%.

For commercial vehicles (trucks), the vehicle weight reduction of 1000kg per year, according to the annual driving 100,000 kilometers, the user can benefit 35,000 ~ 70,000 yuan.

If the application ratio of aluminum trailers in China reaches the same level of 70% in developed countries, it can reduce fuel consumption by 65.62 million tons a year and reduce carbon dioxide emissions by 190 million tons.

Lightweighting makes it possible for commercial vehicles to load more goods in compliance, and while safeguarding road traffic safety, it can significantly improve fuel economy and the transport efficiency of the logistics industry.

Tianhe Casting Group had helped our client codeveloped many products to help our clients reducing weight on the commercial trucks.

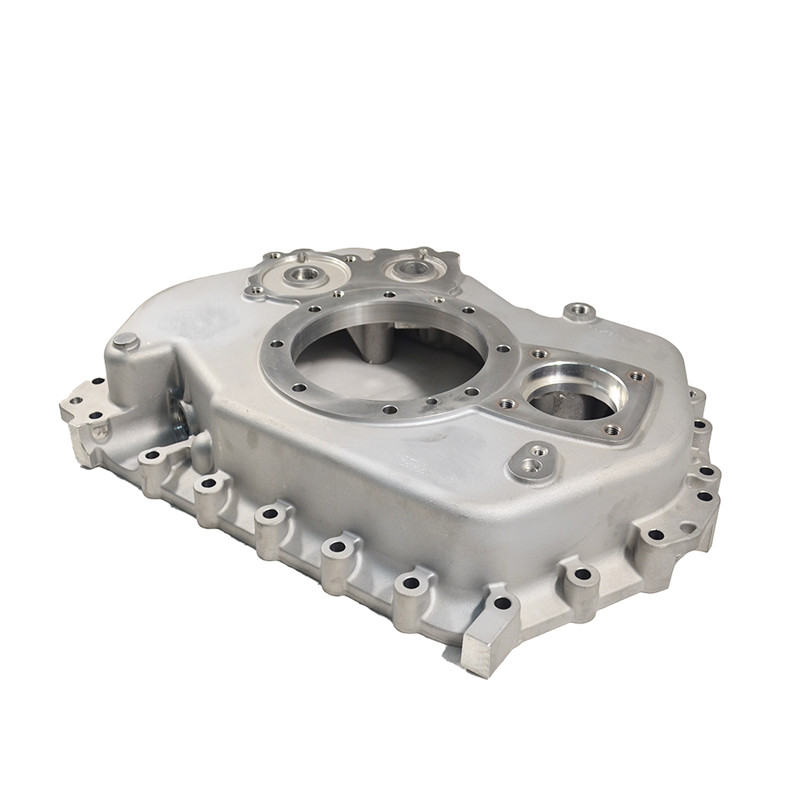

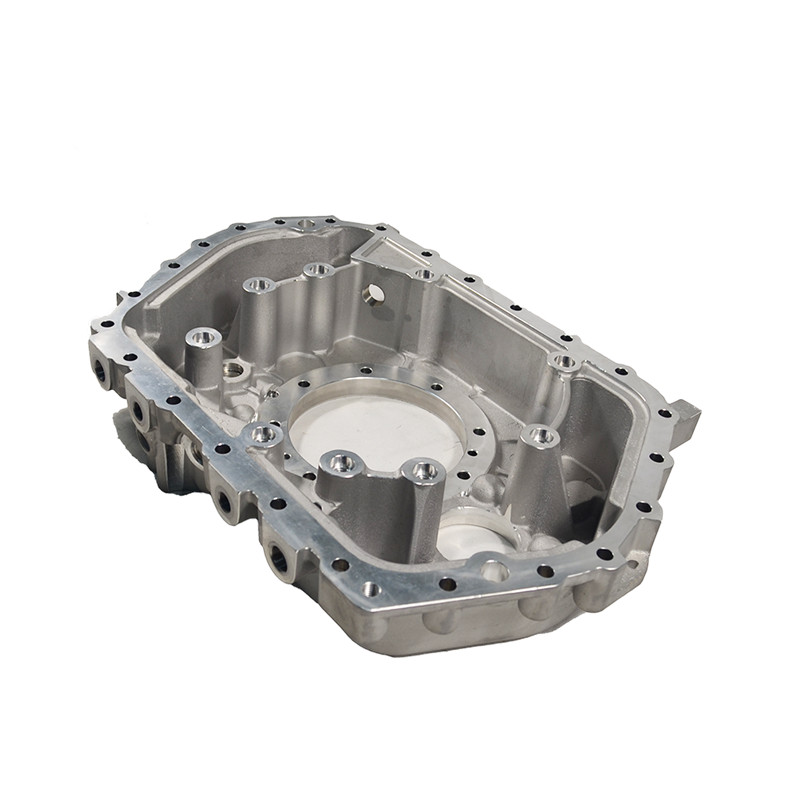

Such as the gearbox housing developed for Sinotruck Group. Originally, the gearbox housing was made of iron.

But commercial truck companies are all seeking lightweightinging of automotive in order to meet the CO2 emission goal set by the Chinese government as part of the carbon peaking and carbon neutrality plan.

China's new energy vehicle sales will be 1.06 million units in 2019 and are expected to rise to four or six million units in 2025.

A large number of new energy vehicles use aluminium for product lightweight design, such as Tesla's all-aluminium die-cast chassis and the ModelS which uses an all-aluminium alloy body to effectively reduce body weight.

The Azera ES8 body-in-white weighs only 335kg, with an aluminium rate of 95.8%, the highest in the world.

The rapid growth of new energy vehicles and the rising demand for aluminium will also promote the rapid development of the aluminium industry.

Additionally, we are also working with many electric car companies to decrease car weight.

Tesla, the leading company in the electric car field, has released their annual report indicating the importance of improving battery performance and reducing car weight. Aluminium die castings are used in three main areas: powertrain, chassis systems, and bodywork.

With the advantages of many years of experience in die casting and casting for automotive, Tianhe Casting Group has effectively developed steering knuckle brackets for Chongqin Jinkang Powertrain New Energy Co., Ltd (Sokon), marking a significant step for Tianhe Casting Group in the move of lightweighting.

Post time: Jul-07-2022