In the manufacturing process of die casting, there are a lot of measurements that require precise data information, such as the chemical composition ratio, furnace temperature, injection pressure, and cycle time in the casting process. It's no longer enough to capture data on paper, in excel, or even in other outdated quality check software. The reason why these practices were abandoned is that they were labor-intensive, time-consuming, error-prone, and have insufficient data to use. The process of die casting is enormous, and the measurement of the product is extremely precise. Therefore, it necessarily needs to be modernized in the process and management.

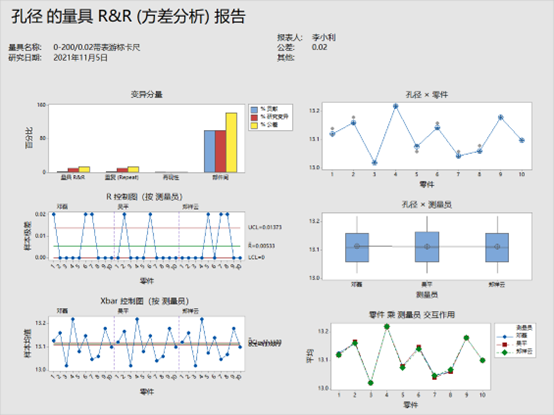

Moreover, according to different usage of the products, different wall thickness, weight, metal strength, porosity, and surface roughness should also be captured for data analysis and quality check. Adopting an online SPC (statistical process control) station can mean a new way to capture data, control processes, drive continuous improvement, and meet customer demands for reports that substantiate a commitment to consistent quality.

We have discovered several benefits of using an online SPC station in our Machining Division:

1. It can be classified and controlled according to the name of the tested workpiece, part number, inspection item, etc.

2. The system automatically calculates the statistical control limit of each test item and uses it for processing and debugging guidance.

3. In daily production, the system automatically judges whether the processing process is out of control according to the daily detection data and provides early alarms for the production system to prevent the generation of waste products.

4. All testing items can be analyzed by process capability and displayed in charts, so as to facilitate daily processing site quality management and subsequent continuous improvement.

5. The measurement data can be stored permanently, which is convenient for traceability.

Post time: Jun-08-2022