FMEA (Failure Mode and Effects Analysis) is important for several reasons, primarily because it serves as a proactive risk management tool that helps organizations identify, assess, and mitigate potential failures in products, processes, or systems.

-

What is FMEA?FMEA (Failure Mode and Effects Analysis) is a systematic risk assessment tool that analyzes the potential failure modes and their consequences of a product or process. It aims to identify and assess risks, so as to take effective measures to reduce or eliminate them.

-

The Purpose and Role of FMEAFMEA aims to identify potential problems in advance and develop preventive measures to reduce the possibility of failure. Its role is mainly reflected in the following aspects: improving product reliability, reducing quality costs, optimizing the design and production process, and enhancing customer satisfaction.

-

Limitations of FMEALimitations include the subjectivity of analysts and information incompleteness. These issues should be kept in mind when using FMEA.

-

When to Carry Out FMEAFMEA should be carried out in the early stages of product design and process planning, in order to detect problems and take measures in a timely manner.

-

Basic FMEA and Family FMEAThis section explains the difference between basic FMEA and family FMEA, as well as their application scenarios, to help you better understand the implementation of FMEA.

-

Reasons for Poor FMEA Implementation and SolutionsThis section analyzes common problems in the FMEA implementation process, such as lack of teamwork and incomplete analysis, and proposes corresponding measures to solve these issues.

-

FMEA Project Planning: The 5T MethodThe 5T method includes: Team (team), Tools (tools), Timing (time), Technique (technology), and Training (training). This method provides practical project management ideas.

-

FMEA Time Node RequirementsThis section emphasizes the importance of FMEA time nodes and provides specific time node requirements to ensure the smooth implementation of FMEA.

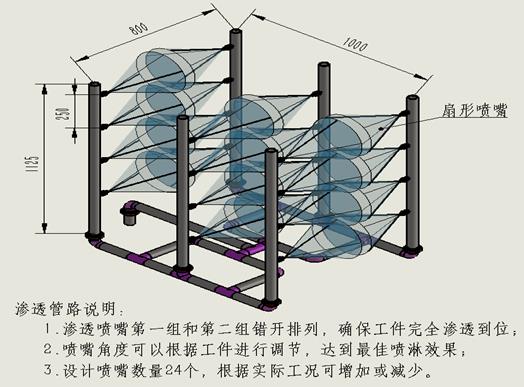

Number of nozzles and the layout of the fluorescent sprays

Post time: Aug-04-2024