The dominant reason for a casting factory to capture the real-time manufacturing data is to keep the machines consistently and correctly running at certain levels.

It is crucial to use an online Statistical Process Control (SPC) workstation, not only to capture when key characteristics are off-target but also when corrective action needs to be taken and inspections completed into an additional process.

As a well-established science method, online SPC’s evaluation criteria are all based on trend rules and measures of variability limits. It is thus able to accurately determine when there is an assignable cause variation and make adjustments before manufacturing out-of-spec parts.

In addition, users are capable of creating rules to detect exceptional patterns and behaviors that occur in the CNC machining process. On-screen visual updates, prompt descriptions, audible alerts, email notifications, or color-coded alerts shown on SPC dashboards can all be used to notify users of the defects during inspections.

Specific product measurements and process parameters require the use of SPC, which is a popular starting point when seeking to improve the die casting process.

In other words, the improvement of the process is inseparable from the foundry with the modern data acquisition system. At the same time, the real process improvements are dug up in the entire arsenal using the SPC metric.

SPC has accurate data capture capabilities to ensure that the correct data is available, especially with its built-in search and analysis capabilities that bring attention to where unnoticed problems occur.

In the extended supply chain, various die casting factories can be considered as a link to the customer as the manufacturer.

Customers who are manufacturers like to adopt advanced quality methods, which often include quality reporting standards that suppliers need to follow. For example, companies regularly provide SPC data in the form of quality reports and data summaries.

The good point is that the use of SPC not only greatly assists die casting plants in modernizing their operations, but also meets customer SPC-related demands. Overall, the SPC system is capable of satisfying any external reporting requirements when automated data collection methods are established.

The use of online SPC stations represents the higher product quality in the casting industry, forcing traditional casting and CNC machining factories to adopt the modernization in the factory.

By employing statistical process control, manufacturers can ensure part characteristics are produced within tolerance for consistent and reliable production. The key to improving manufacturing productivity is adopting computer-integrated manufacturing and controlling methods.

As Kiran (2016, p255-259)1 pointed out in his book, “The superiority of SPC … is that it emphasizes early detection and prevention of problems, rather than the correction of problems after they have occurred.”

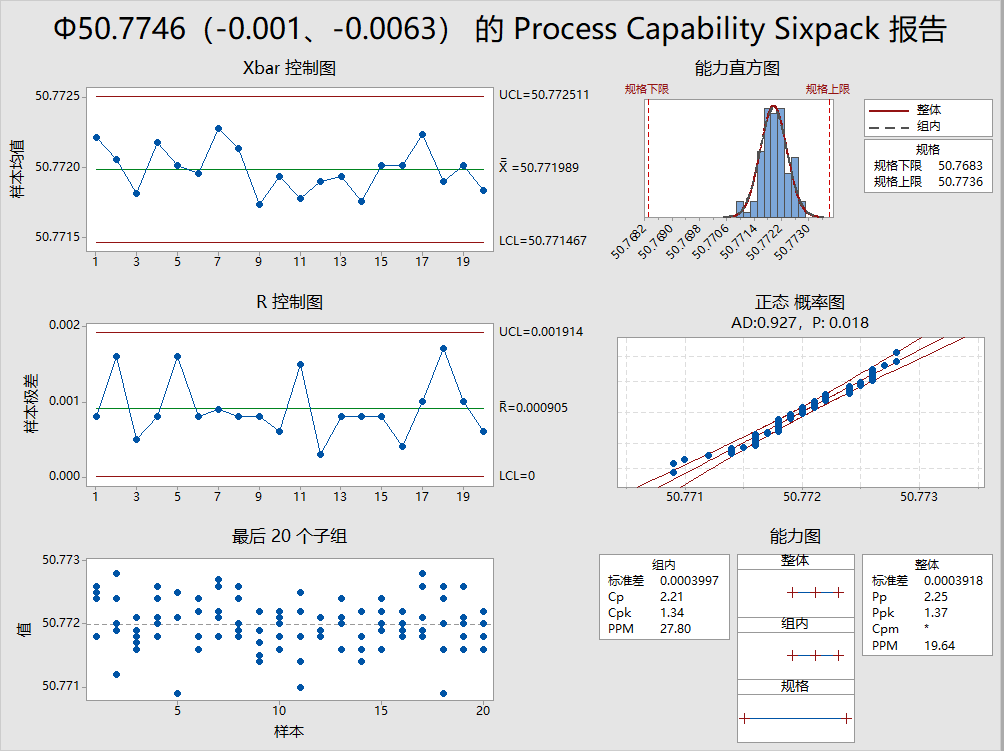

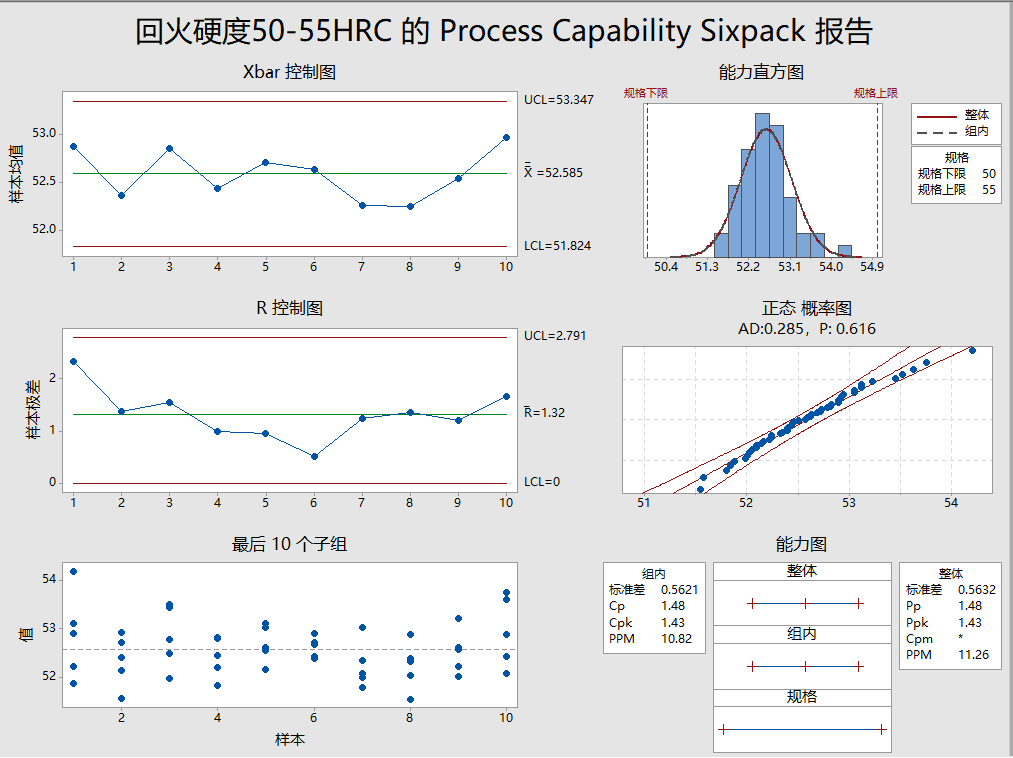

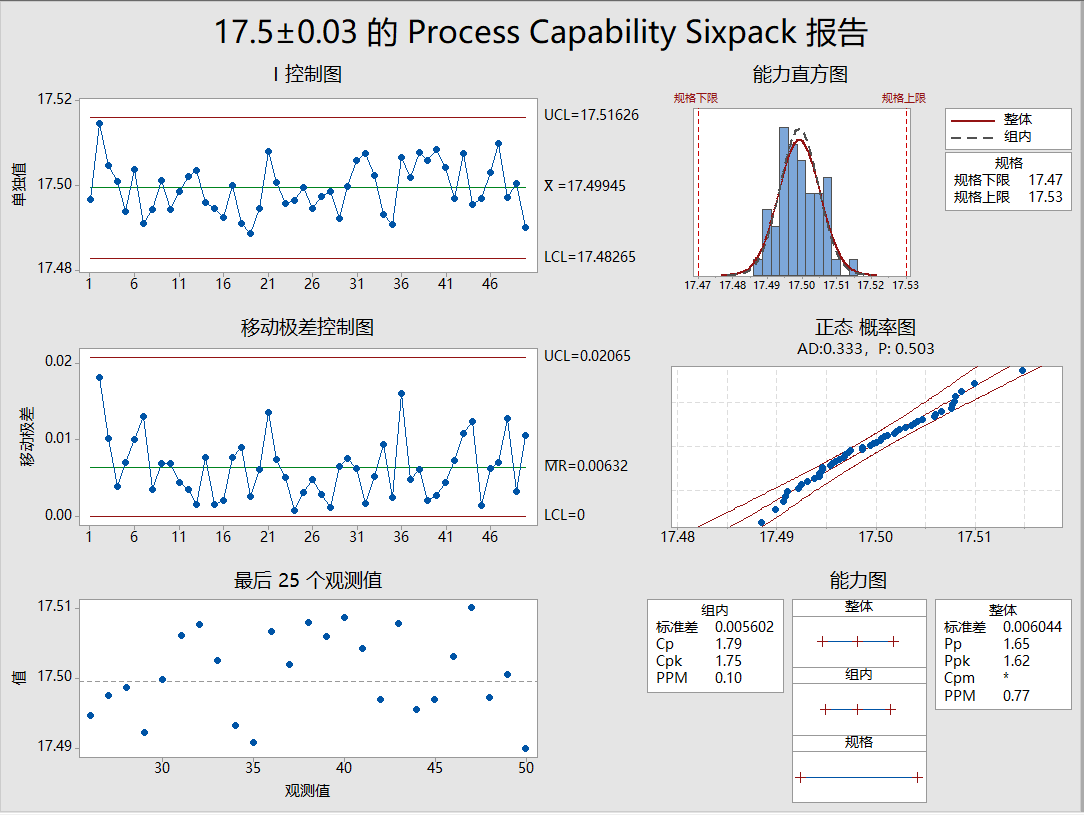

The data collected from using SPC are useful and valuable for future evaluation and control. The most common measures conducted by SPC stations are Cp, Cpk, Pp, and PpK.

Cp and Cpk are the process capability index, often used in a matured production process. Pp and Ppk are the process performance index, used for the new product development stage.

Because in the automotive industry (as Tianhe Casting’s main product range), every product is designed to have a long-usage time which often leads to mass production with repeated products made.

That is why we often use Cp and Cpk in our quality control reports.

After implementing the online SPC station, our quality control department saw a significant decrease in examination time and labor waste during production. For more on-site improvement, please view our other articles.

Our quality team can quickly separate the significant data and create thorough data sets with detailed inspection results, generating a comprehensive statistical result if the quality check is required by customers or internal checks.

Having the ability to prove the capability of both parts and processes over time undoubtedly improves customer satisfaction and accelerates business growth.

In summary, a statistical process control workstation can effectively reduce production costs and reduce management costs, thus improving the actual efficiency of the enterprise.

The rate of product failure has seen a significant decrease which leads to a decrease in reworking. It can enable the quality control staff to better manage and understand the product implementation quality system and better manage the equipment.

Moreover, it helps enterprises to provide core competitiveness, thus enhancing the reputation of the enterprise, to win more customers for the enterprise, and to broaden the market

Reference:

1. Kiran, D.R., 2016. Total quality management: Key concepts and case studies. Butterworth-Heinemann.

Post time: Jun-16-2022