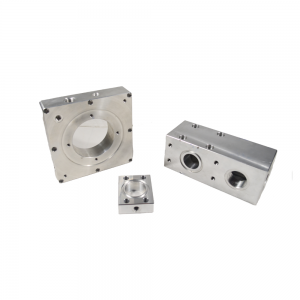

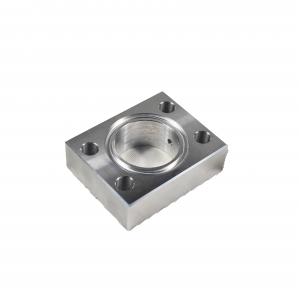

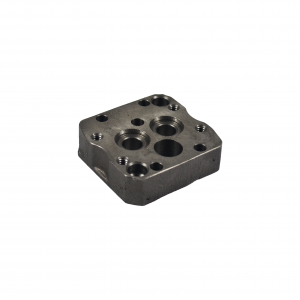

OEM Control Valve Block, Hydraulic Aluminum Alloy Valve Blocks

Product description

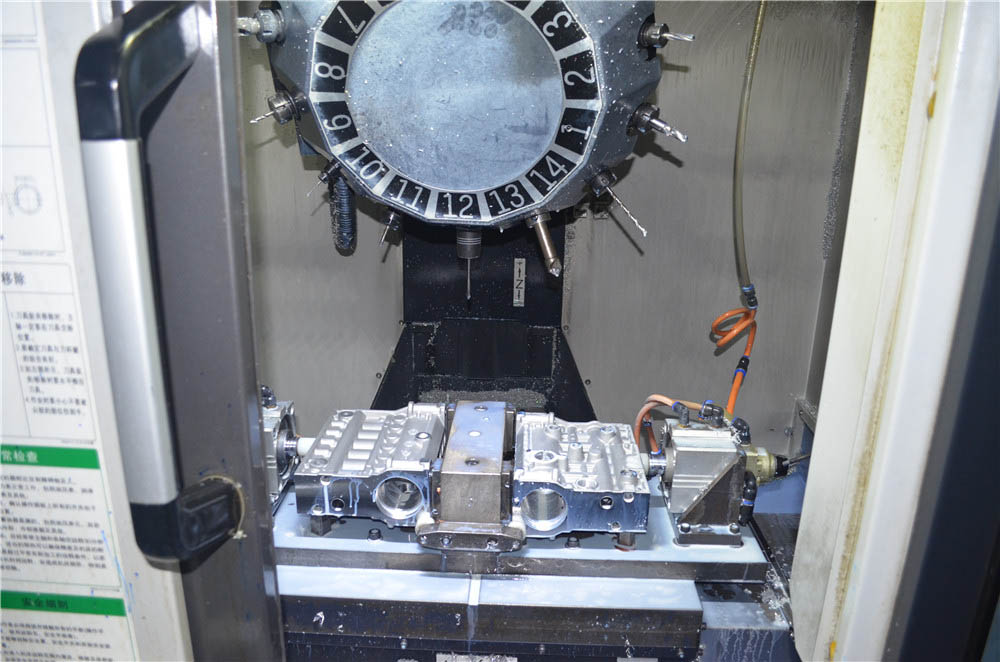

CNC Machining can be used in a wide variety of industries and applications, for example medical, consumer, aerospace, automotive, military defence and industrial. We have over 100 CNC Machines, imported from Japan and Korea. Most of our CNC machining centres are equipped with 3 and 4 axis automation to handle simple to complex low volume runs and mass productions. Our machining capacities include CNC turning, CNC milling, and precision machining. We are able to undertake projects of different sizes. The available manufacturing materials are mainly metal, including aluminium alloy, iron, bronze/brass, stainless steel, and titanium. We are able to offer a one-stop service for aluminium and iron casting customisation as well. Different surface finish treatment is also available such as polishes, electrophoresis plating, clear or coloured anodizing and any custom coatings. We are also aware of the importance of product quality, therefore we are always training our workers to keep the 5S system in mind. Additionally, we have added SPC Workstation where the examination data is recorded and uploaded to our cloud instantly for inspection.

Aluminum/Aluminum Alloy

Brass / Bronze

Carbon Steel

Stainless Steel

Titanium

Grey Iron

3 axis Machining

4 axis Machining

Turning

Milling

Precision Machining

Small Batch Production

Prototype CNC Work

1. How long is the normal use of your mould?

A metal mould would normally last 100,000 makes.

2. Which customers' factory inspections have your company passed?

We have now passed the Global Quality System proposed by Cummins Chongqin Engines Group.

3.What patents and intellectual property rights does your product have?

We have more than 40 patents in the casting and machining field, including 4 inventional patents.

4. Does your company charge mould fees? Can it be returned? How do we return it?

Yes, we do charge metal mould fees but it is a one-off fee. It is a non-refundable fee.

5. What is the total production capacity of your company?

Our maximum monthly production capacity is 700 tons.

1. Customer Provide Drawings

2. Engineers provide quote for customer

3. Quote accepted by customer

4. Sample mold making

5.Send the first samples and mould for customer inspection

6. Casting

7. CNC Machining

8. Quality control

9. Surface treatment