1. Customer Provide Drawings

We believe good communication sets a good start to a project. Before any production, we would like to invite our customers to have a kick-off meeting in order to discuss and confirm the drawings.

2. Quotation Preparation

Engineers will discuss the drawings and provide the quote for the customers. Within 1-7 days, engineers will send you a quotation with a detailed cost breakdown and a summary of technical recommendations, risks and insights.

3. Quote Accepted

After our cost and risk evaluation, at the time, customers should be fully aware of the project process. Customers can decide whether to work and pay the mould cost upfront.

4. Sample mould making

The sample production is due to start once mould payment has been accepted. An outer mould is often made of 45 steel or other material depending on customer's requirements.

5. Sample inspection

Once samples are finished, they will be sent for inspections in the fastest way. For domestic customers, we often choose SF to deliver our samples. For oversea customers, DHL, USP or other shipping methods can be used.

6. Mass Casting Production

Mass production will be carried out in accordance with the agreed drawings and special requirements. Our Sales Manager will report to customers about every step of the production. Customers are welcome to have a factory visit during the production. Considering the Covid-19 situation, virtual visits with video calls can also be set up for customers.

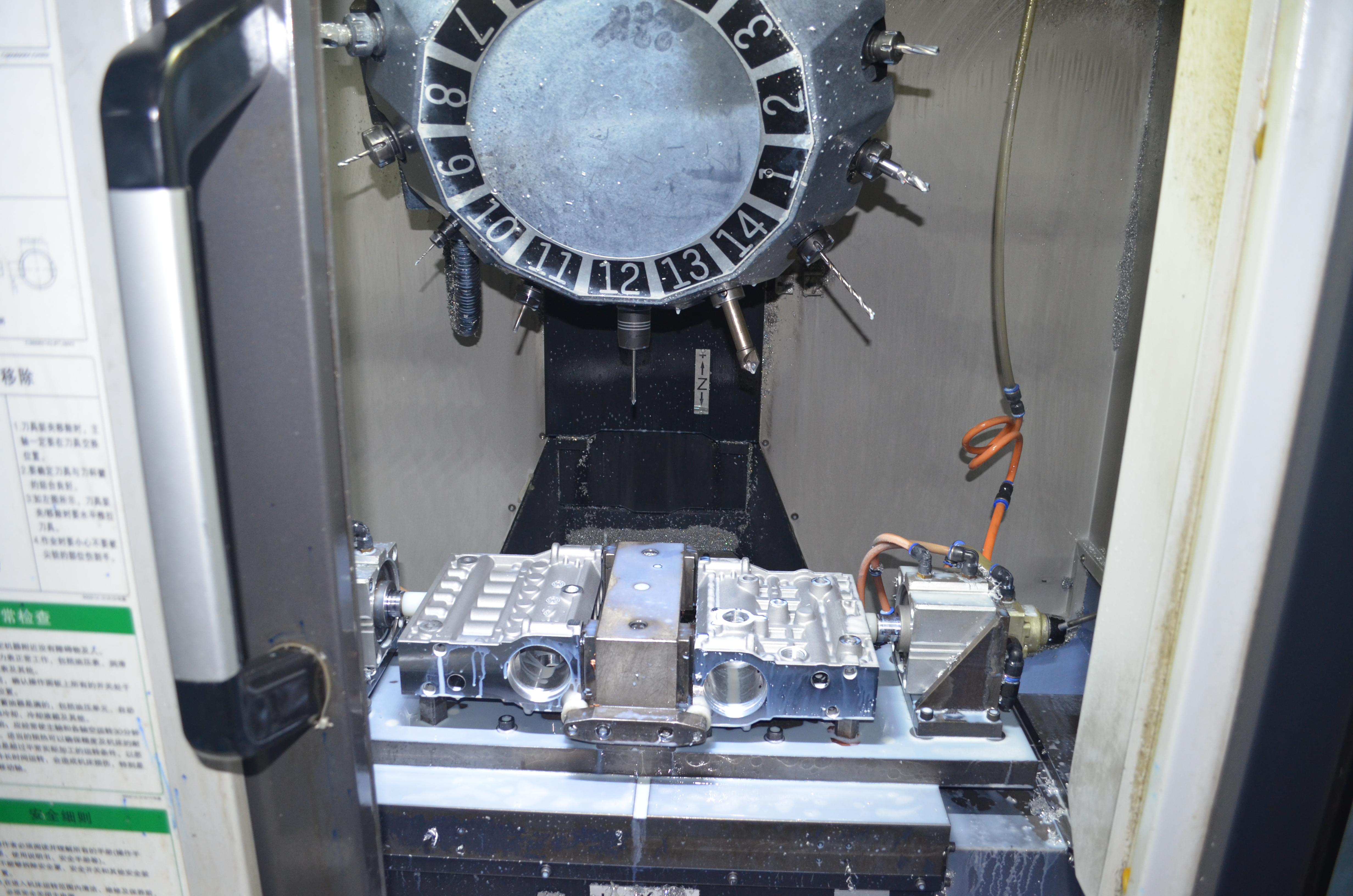

7. CNC Machining

Tianhe Casting Group maintains a comprehensive in-house machining facility with over 120 machining centers, offering a wide range of capabilities such as milling, drilling and precision machining. Customised machining toolings, jigs and fixtures, and machining process is delivered to meet customer's needs.

8. Surface treatment

Depending on the mechanical, physical, and chemical properties of the product, different surface treatments will be applied such as anodizing, electrophoresis, polishing.

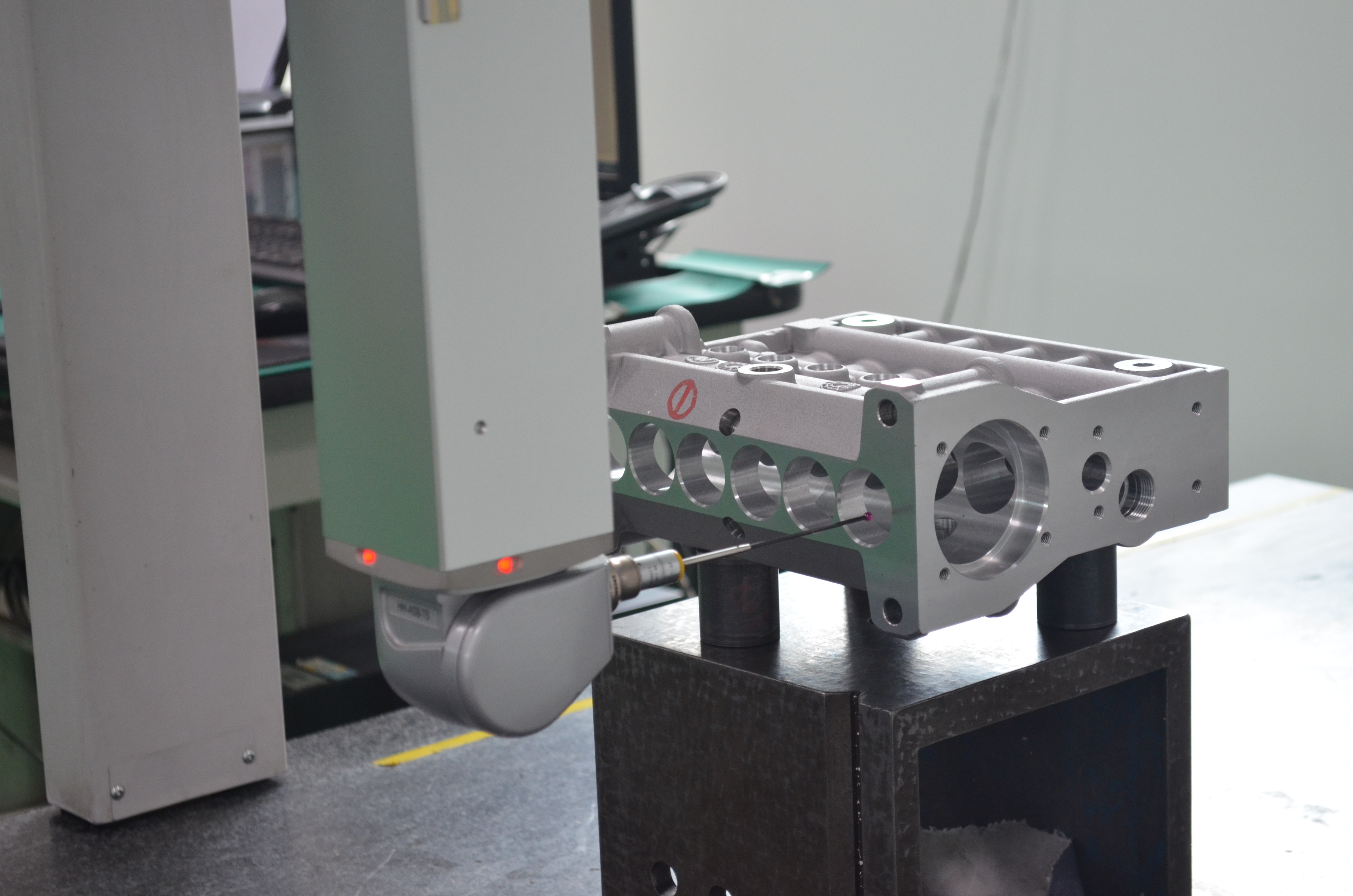

9. Quality Control

Multiple quality control methods are used throughout the whole production process. We have mechanical inspections at the beginning of the casting stage. Further quality assurance after CNC Machining includes CMMs and Metallographic examination, crack detection etc.

10. Delivery

Worldwide delivery can be arranged according to the customer's need.

Our factory is located in central China, with a 3-hour drive distance to the nearest river harbour and a 1-h drive to the rail station. We also own our logistic team which allows us to ship products to any domestic place.